With the advancement of bioreactor design and control, the requirements for sensing technology have also changed. For example, single use bioreactors (SUB) are becoming increasingly popular, and disposable solutions for pH and DO have also been introduced.

However, most of the sensors currently used for SUB are still those used in traditional stainless steel bioreactors, which to some extent are not suitable for SUB design.

PH sensor: The pH value of the culture is a key variable in the operation of the bioreactor. PH sensing technology can be roughly divided into the following categories: electrode based porous glass electrolyte filled sensors, ISFET pH (Ion sensitive field effect transistor pH) sensors based on MOSFET (Metal oxide semiconductor field effect transistor), pH sensors based on optical properties, potential sensors, and electrochemical sensing technology sensors.

Glass pH electrodes are still widely used in the vast majority of pH sensors due to their superior repeatability, durability, and precise Nernstian responsiveness.

Ion selective electrodes (ISE), such as electrochemical pH electrodes, are a major subcategory of sensors based on the principle of potentiometry. Potentiometry is a method of measuring potential where there is no current between electrodes.

Compare the potential changes on the solid membrane between the internal solution analyte and the reference electrode using the indicator electrode. The current pH sensor design usually includes a reference electrode inside the probe, resulting in a bulky structure.

The main challenge of pH sensors with glass electrodes is the fragility of the glass material and the problem of scaling when used in complex media.

Electrochemical sensors use electrodes to convert analytes into measurable substances. For example, gas sensors measure the concentration of gas by oxidizing or reducing the target gas on the electrode, and measure the generated current of the conversion.

An electrochemical sensor consists of three electrodes: a working electrode, a reference electrode, and a counter electrode. The working electrode undergoes redox reactions with ions.

In addition to the electrode, there is also a breathable membrane inside the sensor to separate water-based components from gases, adjust the amount of gas reaching the working electrode, and prevent internal leakage of the sensor.

ISFET sensing technology uses field-effect transistors, which are ion sensitive and can be used to measure ion concentration in solutions. The source and ground electrodes are grounded to the substrate and connected to the circuit.

The attachment of analytes/ions to the gate film can cause a change in the potential between the source electrode and the ground electrode, which is a measure of the concentration of ions/analytes.

ISFET is considered the first biosensor field-effect transistor used for biological solutions, and is therefore also known as a biological field-effect transistor.

Compared with electrochemical sensors, optical sensors only measure the activity of H3O+ions. Optical sensors have several advantages: small size, continuous measurement, and no need for separate reference electrodes.

Photobleaching is the most important factor affecting the accuracy of this type of sensor. The breakage of covalent or non covalent bonds generated by non-specific binding triggered by excitation light can lead to photobleaching of indicator dyes, rendering them unable to emit light.

Over time, the sensor becomes inaccurate. The main trend in the development of optical sensors is miniaturization. This will reduce costs and improve mass producibility.

Optical pH patch is such a small optical sensor. The optical pH patch combines the pH sensor onto an adhesive disc attached to the surface of the bioreactor. Another latest research area is the development of disposable optical sensors that can be used in conjunction with disposable bioreactors.

The anaerobic process heavily relies on "manual experimental analysis" and "qualified experimental operators". The control measurement of this process involves methods such as spectroscopy and titration.

At present, the biological processes being studied require different spectroscopic techniques due to the magnitude of the energy changes involved. Spectral monitoring of biological processes often generates a large number of spectra, each with significantly lower information content than the amount of data.

Quickly extracting useful information from a large amount of data is crucial. Fluorescence spectroscopy emerged at the beginning of the 21st century. The fluorescence measurement of the reduced form of NAD (P) H is the most popular fluorescence sensor.

Temperature control in bioreactors is a mature technology that can typically achieve accuracy of ± 0.5 ° C or higher. Typical temperature sensors used in industry include thermocouples, resistance temperature detectors (RTDs), and thermistors.

The selection of specific temperature measuring instruments depends on the stability, sensitivity, accuracy, linearity, and sterilization of the sensor. PT100 is commonly used for temperature sensing in bioreactors.

Platinum RTDs are used because they provide a nearly linear response to temperature changes, are stable and accurate, can provide repeatable responses, and have a wide temperature range. RTD is often used in precision applications due to its accuracy and repeatability.

The temperature control in animal cell bioreactors is usually simpler than in microbial fermentation tanks, as cell culture has lower metabolic activity and requires less heat to be removed from the reactor.

Standard single blade impellers or single baffle mixing tanks usually have the disadvantages of uneven shear characteristics and energy dissipation. Has a significant impact on sensitive microorganisms.

In a multi blade impeller system, reducing the impeller speed to obtain equivalent power dissipation will result in a decrease in the maximum shear value generated. It should be noted that regardless of whether it is a single blade impeller or a multi blade impeller, the shear force required for the rupture at the bubble interface is the same.

Therefore, in a multi blade impeller system that consumes the same total power, the overall cell damage rate caused by fluid shear is expected to be lower. Therefore, when microorganisms are highly sensitive to shear, a multi blade impeller system will be the preferred choice.

During the installation of the impeller, instruments such as tachometers are usually used to check whether the required speed matches the reading in the tachometer, in order to verify whether the rpm value is close to the optimal value. Use CFD (Computational Fluid Dynamics) modeling and mixed prediction of various features to achieve the desired blade speed and control.

During the fermentation and cultivation process, in addition to temperature, pH value, DO, and stirring speed, online exhaust gas analyzer is also an important sensing technology for process control.

Exhaust gas analyzers are commonly used in VOC composition analysis or specific gas analysis, and optical array sensing has excellent performance in detecting and identifying various analytes (including hazardous compounds), which can be used to detect and identify VOCs collected in the headspace of bioreactors.

A tail gas analyzer with CO2 and DO sensors can be used to calculate OUR, which is also one of the key parameters for microbial growth. This analysis technology can be divided into non-invasive sensing technology, which is used to detect CO2 in the gas at the tail of the tank, O2

Analyze the respiratory quotient OUR of metabolic processes and monitor changes in fermentation processes. Online monitoring can accelerate the analysis speed without the need for sampling or pretreatment.

It can be directly connected to the fermentation tank exhaust pipe (traditional exhaust analyzers require dehumidification and other pretreatment of fermentation exhaust).

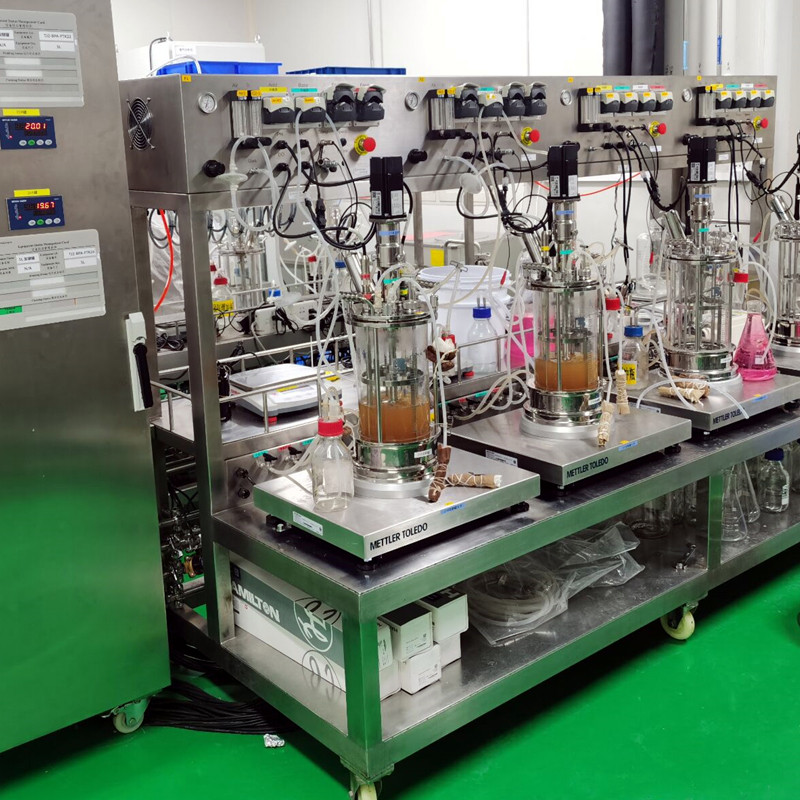

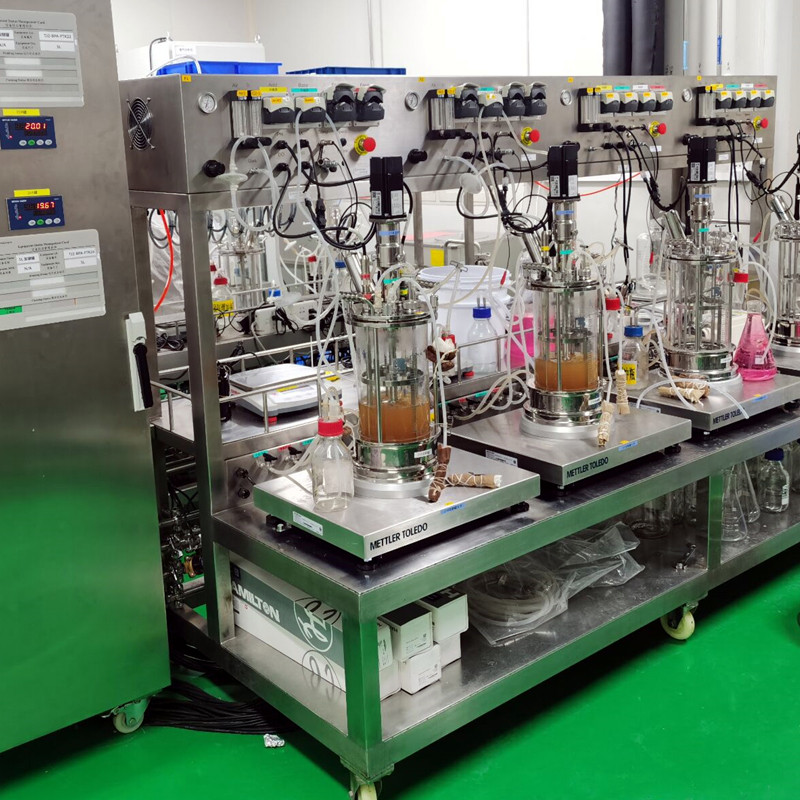

Parallel bioreactors can choose multi-channel exhaust analyzers, such as four channel, eight channel, and dozens of channels. It can achieve simultaneous online parallel monitoring of multiple tanks.