Temperature Control Scheme in Biological Reactions (Latest)

When the capacity of the culture dish equipment is between 2.2 and 2.8 liters, it is desired to obtain the controller parameters through parameter self-tuning when powered on, and then raise the temperature to the set temperature.

Heating overshoot<0.5 ℃, steady-state temperature fluctuation ± 0.1 ℃, heating time requirement not exceeding 50 minutes.

This scheme can simultaneously identify heating and cooling, but the relay setting takes 30 minutes, resulting in a complete heating time of about 1 hour.

Control method: Temperature control PID+relay self-tuning scheme, adopting dual degree of freedom mode. Control output: Heating&cooling mode identification

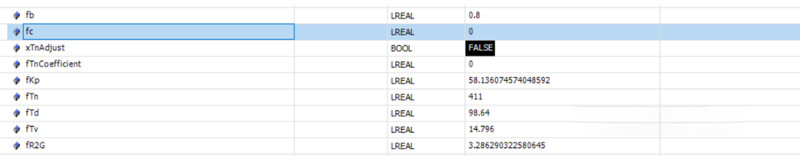

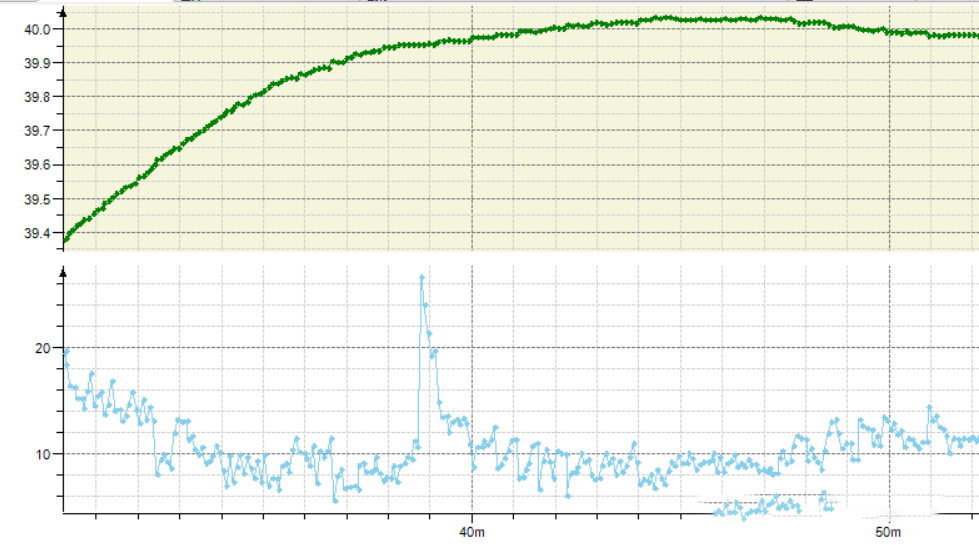

method: Relay identification for cold machine start-up, initial temperature 17.4 ℃, set temperature 40 ℃ Test effect:

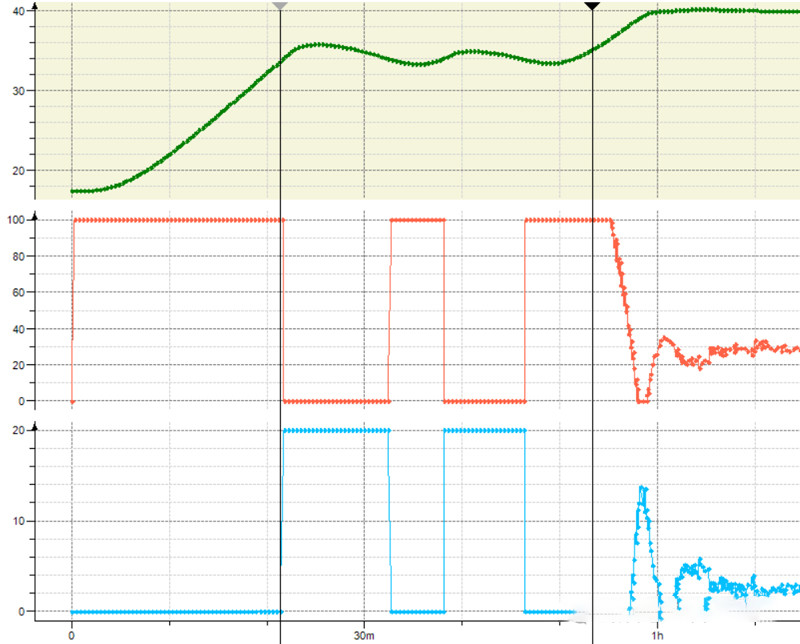

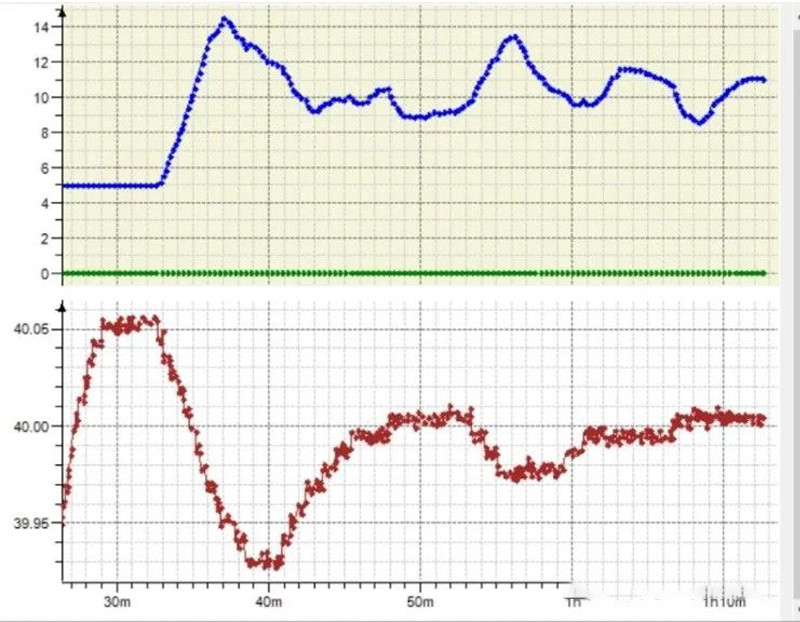

The overall temperature rise waveform is as follows, and the identification time of the relay self-tuning section is about 30 minutes:

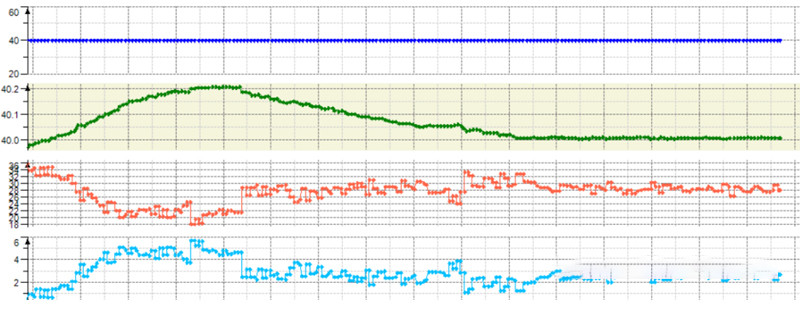

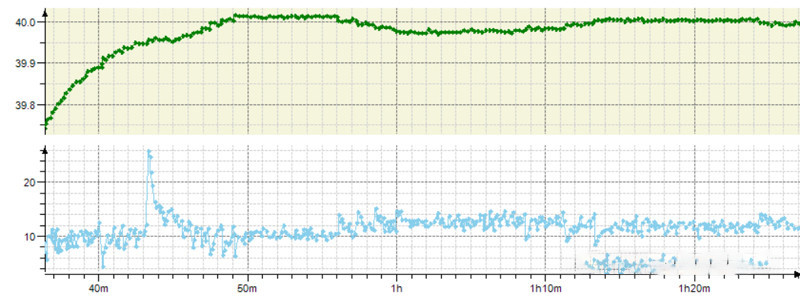

The waveform of heating up to the set temperature is as follows:

Control method: Temperature control PID+relay self-tuning scheme, using integral separation mode. Control output: Heating&Cooling mode identification method: Relay identification for cold machine start-up, initial temperature 17.9 ℃, set temperature 40 ℃

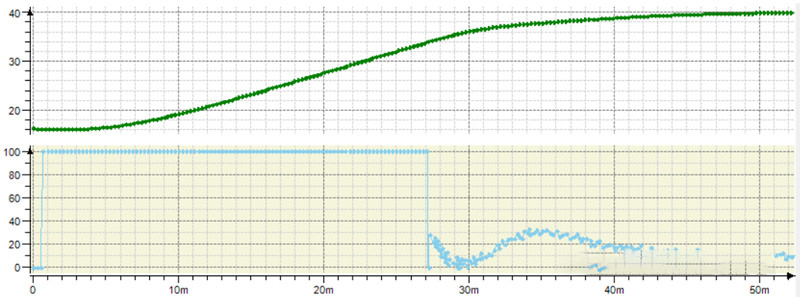

Control method: Temperature control PID+step self-tuning scheme. Control output: Single heating mode identification method: step self-tuning scheme for cold machine startup, initial temperature of 22 ℃, set temperature of 40 ℃

When step tuning is used to identify heating and cooling, the overall time is equivalent to the relay method and cannot save time. When only heating is set, the time required for self-tuning can be reduced.

To save heating time, eliminating the identification of refrigeration and only identifying the heating capacity of the system through steps can shorten the overall time. Test effect: Take 39.9 ℃ as the temperature adjustment time.

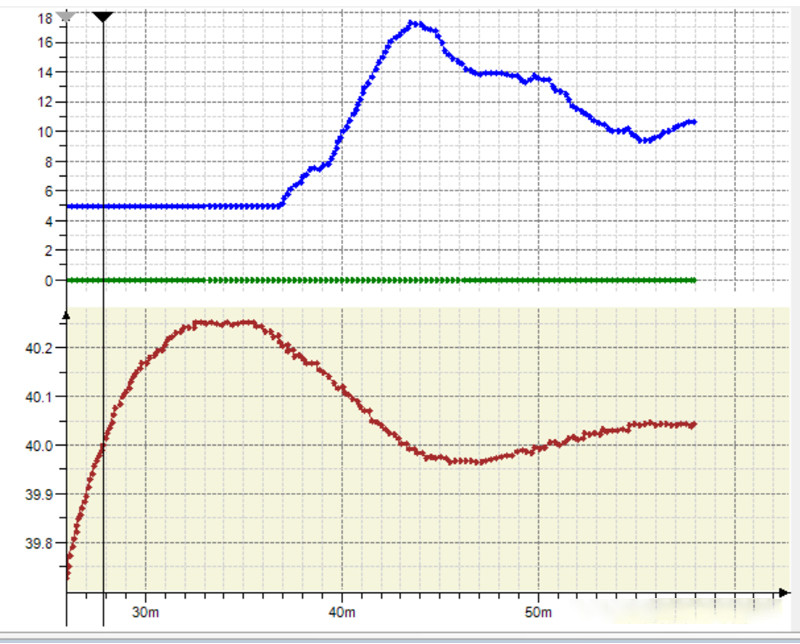

Control method: Temperature control PID+step self-tuning scheme. Control output: Single heating mode identification method: Step wise self-tuning scheme.

The refrigeration machine starts with an initial temperature of 24 ℃ and a set temperature of 40 ℃. Test effect: Take 39.9 ℃ as the temperature adjustment time

Control method: Temperature control PID+step self-tuning scheme. Control output: Single heating mode identification method: Step wise self-tuning scheme.

The refrigeration machine starts with an initial temperature of 24 ℃ and a set temperature of 40 ℃. Test effect: Take 39.9 ℃ as the temperature adjustment time

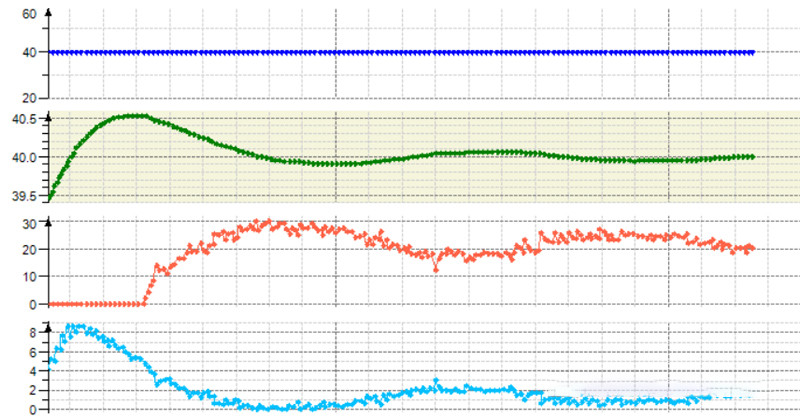

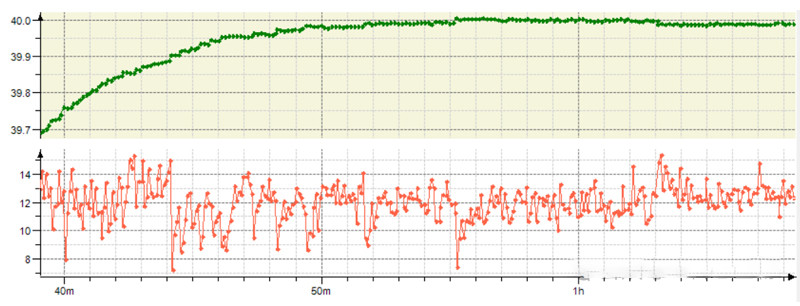

Control method: Temperature control PID directly heats up, with parameters set in the previous step. Control output: Single heating mode identification method: No identification (step identification parameter) Cold machine startup, initial temperature 16 ℃, set temperature 40 ℃

Test effect: There is no overshoot in temperature, and the temperature adjustment time is set to 39.9 ℃

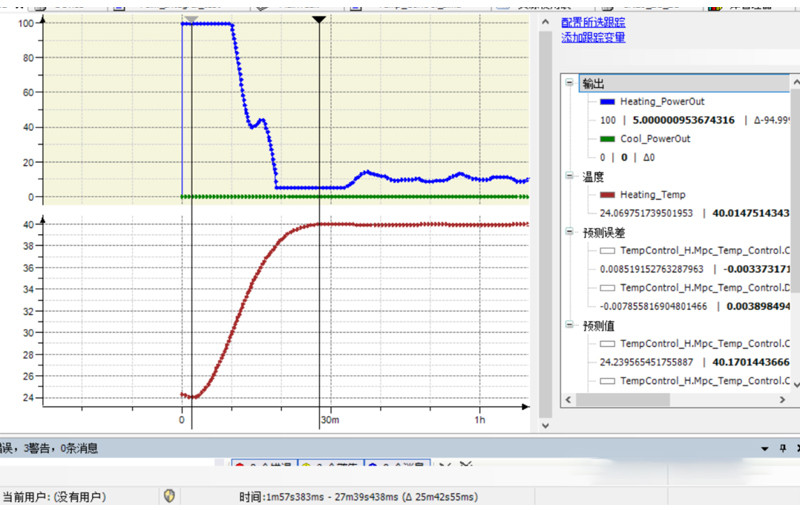

Control method: Model predictive control scheme, heating output lower limit amplitude of 5%. Control output: Single heating mode identification method: No identification for cold machine startup, initial temperature of 24 ℃, set temperature of 40 ℃

Test effect: The overall temperature rise waveform is as follows. Since there is no self-tuning, it saves about 30 minutes of time compared to relay self-tuning:

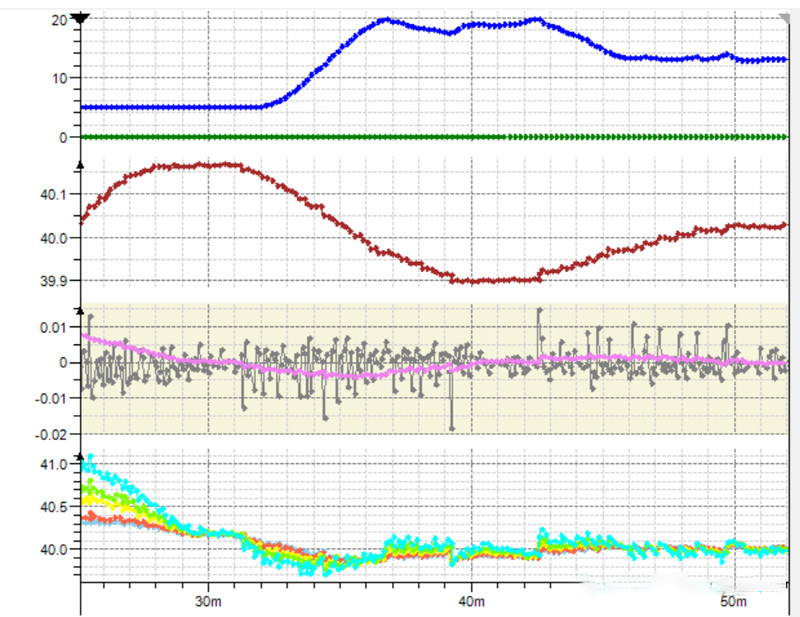

In order to improve the overall heating time, the MPC algorithm does not identify model parameters, but uses an offline identified model, combined with model prediction algorithms, for real-time correction and control.

Relying on MPC regulation to adapt to changes in operating conditions. To verify the adaptability of MPC to different water volumes, the following experiments were conducted:

The water capacity is 1.6L, with an overshoot of 0.05 and a fluctuation range of 0.02. The rise time from 24 ° to 40 ° is 25m42s.

The water capacity is 2.6L, with an overshoot of 0.25 and a fluctuation range of 0.05. The rise time from 26 ° to 40 ° is approximately 27m7s.

The water capacity is 2.8L, with an overshoot of 0.17 and a fluctuation range of 0.1. The rise time from 26 ° to 40 ° is approximately 24m20s.

Bailun has rich experience in the manufacturing of various reactors and pressure vessels. We have a team of experts in the fields of biological reactions, fermentation processes, mechanical manufacturing, and automation control.

Our research and process capabilities are always at the forefront domestically and internationally, providing you with a comfortable, reassuring, and secure product experience.