In the weekend special planning of the "News Live Room" broadcasted on December 1st, CCTV News reported on the PHA Cell Factory of Micro Structure Factory, detailing its technological innovation and application expansion in the production of PHA biomaterials, highlighting the important significance of synthetic biology technology in promoting sustainable development.

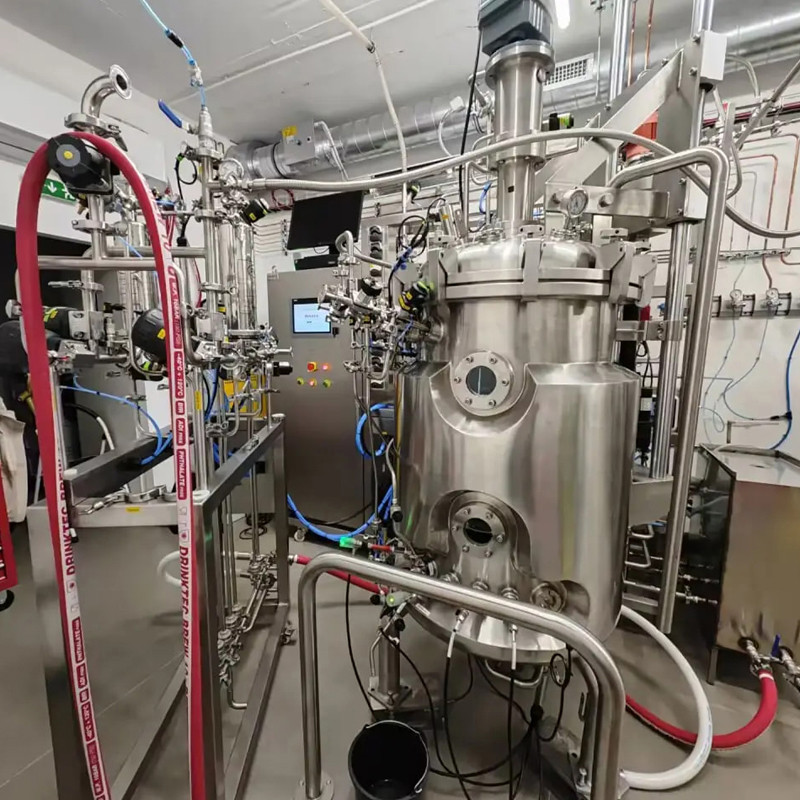

Multiple bioreactors from Bailun have appeared in the news reports, and Bailun is making every effort to contribute to the development of synthetic biology in China and the formation of new quality productivity in biotechnology!

During the weekend special program of "News Live Room" broadcasted by CCTV News Channel on December 1st, reporters visited the microstructure factory to explore how synthetic biology can help halophilic bacteria efficiently produce PHA.

PHA, as a biomaterial derived from the intracellular fat of microorganisms, stands for polyhydroxyalkanoates. It has excellent degradability and biocompatibility, and is expected to replace traditional plastics in the future, becoming a new choice for environmentally friendly materials.

Scientists use synthetic biology techniques to genetically modify and recombine special microorganisms in nature, and precisely regulate their metabolic pathways, thereby endowing them with the ability to produce PHA.

The origin and development of PHA production technology in Microstructural Workshop: The PHA biomaterial production technology in Microstructural Workshop originated from Tsinghua University's "Next Generation Industrial Biotechnology (NGIB Technology)". Since 1992, its research team has been based on the extreme microorganisms extracted from Lake Edin - halophilic bacteria.

After more than 20 years of continuous iteration and optimization, they have successfully cultivated halophilic bacteria into efficient "working bacteria" for producing PHA.

Nowadays, by providing carbon sources for these halophilic bacteria, PHA materials with different properties can be produced.

Production scale and application areas: Currently, Micro Structure Factory has built an intelligent production demonstration line with an annual output of 1000 tons in Shunyi, Beijing, and established a production base with an annual output of 30000 tons in Hubei, demonstrating its solid steps on the path of PHA industrialization.

In terms of application, PHA biomaterials have actively expanded in multiple fields such as catering, packaging, medical, cultural and creative industries, and are expected to be widely integrated into more life scenarios in the future.

For example, it can be used to make disposable tableware in the catering industry, replace some traditional plastic packaging materials in the packaging industry, be applied to biodegradable sutures and other products in the medical field, and be used as an environmentally friendly material in cultural and creative products. This not only reflects the versatility of PHA materials, but also indicates their broad market prospects.

Professor Chen Guoqiang's team at Tsinghua University has made significant progress in producing PHA from carbon dioxide. Professor Chen Guoqiang, Director of the Center for Synthesis and Systems Biology at Tsinghua University, has led a research team to achieve a major breakthrough and successfully developed a new technology for producing PHA from carbon dioxide as raw material.

In the laboratory of Tsinghua University, researchers demonstrated to reporters this innovative process: halophilic bacteria can absorb carbon dioxide gas stored in tanks and convert it into PHA inside the cell. The implementation of this technology benefits from the special properties possessed by the super strains developed by the team.

In the future, with the continuous maturity and application of this technology, it is expected to convert carbon dioxide, a greenhouse gas, into environmentally friendly PHA biomaterials. This not only effectively reduces greenhouse gas emissions and alleviates global warming pressure, but also provides a highly potential solution to the global environmental problem of plastic pollution.

Microstructure Factory has achieved significant results in the research and development, production, and application promotion of PHA biomaterials. Its technological innovation has not only promoted the development of the biomaterial industry, but also made positive contributions to environmental protection and sustainable development.