Bioreactor: From Algae to Cell Culture - Unveiling the Potential of Bioreactor Machines

In the realm of modern science and technology, bioreactors have emerged as indispensable tools with diverse applications ranging from algae cultivation to cell culture. This article aims to provide an in-depth exploration of bioreactors, focusing on their significance, design, functionality, and the impact they have on various fields.

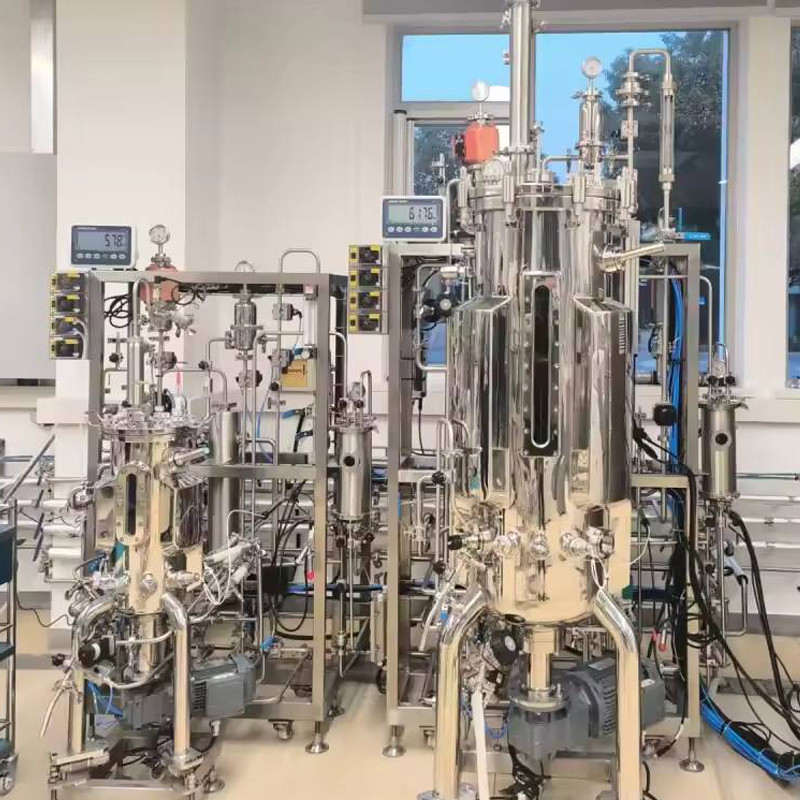

The bioreactor, at its core, is a sophisticated device engineered to create an optimal environment for biological processes to occur. Whether it is the growth of algae for biofuel production or the cultivation of cells for therapeutic purposes, the bioreactor plays a crucial role in controlling and manipulating the conditions necessary for success.

Algae bioreactors have gained significant attention in recent years due to their potential in addressing energy and environmental challenges. These bioreactors are designed to provide the ideal conditions for algae to thrive and multiply. Algae have the remarkable ability to convert sunlight and carbon dioxide into valuable substances, such as lipids and carbohydrates, which can be further processed into biofuels.

The design of an algae bioreactor takes into account several factors. Light penetration is critical as algae require sufficient illumination for photosynthesis. The reactor's geometry and material composition are selected to maximize light absorption while minimizing heat loss.

Efficient mixing of the culture medium ensures that all algae cells have access to nutrients and carbon dioxide. Temperature and pH control systems are also incorporated to maintain the optimal conditions for growth.

In the context of cell culture, bioreactor machines offer a controlled and scalable environment for the growth and manipulation of cells. These systems are essential in the production of therapeutic proteins, vaccines, and regenerative medicine. Cell culture bioreactors provide precise control over parameters such as oxygen supply, nutrient concentration, and waste removal.

This level of control is crucial for maintaining cell viability, promoting cell proliferation, and ensuring the quality and consistency of the final product.

The functionality of a bioreactor is not limited to providing a suitable physical environment. It also involves the monitoring and regulation of various biochemical processes. Sensors within the bioreactor constantly measure parameters like cell density, metabolite production, and dissolved gas levels. This real-time data is fed into a control system that adjusts the operating conditions accordingly, ensuring the process remains on track and optimized.

One of the significant advantages of bioreactors is their scalability. From small-scale laboratory setups to large industrial-sized systems, bioreactors can be adapted to meet the demands of different applications. This scalability is crucial for translating research findings from the laboratory to commercial production, enabling the efficient manufacturing of products on a large scale.

Bioreactors 1000l also contribute to reducing the environmental footprint. In the case of algae bioreactors, they offer a sustainable alternative for carbon capture and the production of renewable energy. In cell culture, efficient use of resources and waste minimization are important aspects that align with the principles of sustainable manufacturing.

However, the use of bioreactors is not without challenges. Maintaining sterility is of paramount importance to prevent contamination, which can lead to process failure and product loss.

The complexity of the control systems requires highly skilled operators and engineers to ensure proper functioning. Additionally, the initial investment and operational costs of bioreactors can be substantial, requiring careful economic analysis and optimization.

Looking ahead, the future of bioreactors holds great promise. Advances in materials science, sensor technology, and process control are expected to further enhance the performance and functionality of these systems.

Integration with artificial intelligence and machine learning algorithms will enable more intelligent and adaptive control strategies, improving productivity and quality.

In conclusion, bioreactors have become a cornerstone in the fields of algae cultivation and cell culture, offering unprecedented control and scalability. Their continued development and innovation will undoubtedly play a vital role in driving progress in various industries, from energy and healthcare to environmental sustainability.

As we strive to meet the challenges of the 21st century, the potential of bioreactor technology remains vast and largely untapped, presenting exciting opportunities for researchers and engineers alike.