Cell Culture and Microorganism Fermentation in 60L Stainless Tanks

In the ever-evolving landscape of biotechnology and industrial processes, the role of specialized equipment such as the Cell Culture Fermentation Tank and the Microorganism Fermentation Tank, particularly in a 60L Stainless Tank Fermenter configuration, has become increasingly significant. These tanks are not merely containers but sophisticated systems that facilitate controlled and optimized biological processes, enabling the production of valuable substances and the advancement of scientific research.

The 60L Stainless Tank Fermenter offers a balance between capacity and operational manageability. Its size is suitable for a range of applications, from laboratory-scale research to small-scale industrial production. The use of stainless steel in its construction is a deliberate choice, given the material's numerous advantages. Stainless steel is highly resistant to corrosion, ensuring the tank's longevity and integrity even when exposed to harsh chemicals and sterilization processes. This durability is crucial in maintaining a contamination-free environment, which is paramount for the success of cell culture and microorganism fermentation.

Cell culture in a fermentation tank presents a complex yet highly controlled environment. Cells, whether they are mammalian, plant, or microbial, have specific requirements for growth, proliferation, and functionality. The 60L Stainless Tank Fermenter is equipped with systems to precisely regulate parameters such as temperature, pH, dissolved oxygen levels, and nutrient supply. Maintaining the optimal temperature is essential as it directly influences metabolic rates and enzymatic activities within the cells. Similarly, pH control is critical as it affects the ionization of molecules and the activity of enzymes involved in cellular processes.

Dissolved oxygen is another key factor. Adequate oxygen supply is necessary for aerobic cellular respiration, which provides the energy needed for cell growth and metabolite production. The tank's design incorporates efficient aeration and agitation mechanisms to ensure a uniform distribution of oxygen throughout the culture volume. Nutrient delivery is also precisely managed to meet the cells' metabolic demands without causing nutrient depletion or accumulation of toxic by-products.

Microorganism fermentation in the 60L Stainless Tank Fermenter has its own unique considerations. Different microorganisms have varying growth kinetics and metabolic pathways, and the tank must be configured to accommodate these differences. For example, in the production of antibiotics using microbial fermentation, the control of growth conditions is crucial to induce the synthesis of the desired compound at the appropriate stage. This may involve manipulating factors such as the carbon source, nitrogen availability, and the addition of specific inducers.

The scalability of processes from smaller laboratory setups to the 60L tank and potentially to larger industrial-scale systems is an important aspect. Data and insights gained from smaller-scale experiments can be used to optimize the parameters and operations in the 60L tank. This scalability allows for a seamless transition from research and development to commercial production, reducing the risks and uncertainties associated with scale-up.

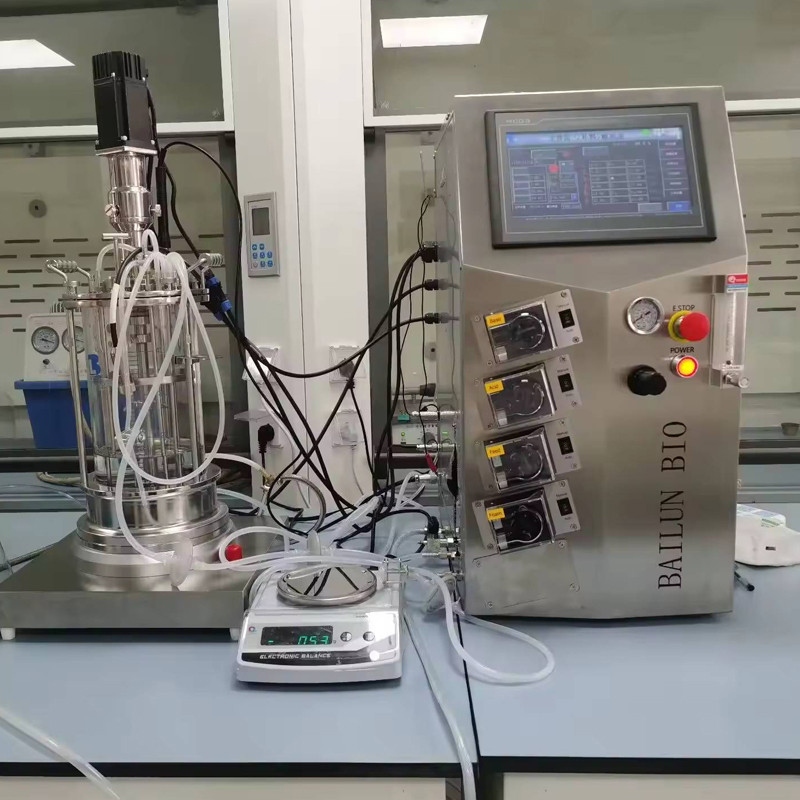

Monitoring and control systems play a vital role in the operation of the 60L Stainless Tank Fermenter. Advanced sensors continuously measure and relay data on various parameters to a central control unit. This real-time information enables operators to make immediate adjustments and interventions to ensure the process remains on track. Additionally, the ability to log and analyze this data over time provides valuable insights for process improvement and optimization.

In the field of biopharmaceuticals, cell culture in these tanks is crucial for the production of therapeutic proteins, monoclonal antibodies, and vaccines. The controlled environment of the 60L tank helps ensure the consistency and quality of these products, which are subject to strict regulatory standards. Similarly, in the food and beverage industry, microorganism fermentation is used for the production of beverages like beer and wine, as well as food additives and enzymes.

The operation and maintenance of the 60L Tank Stainless Fermenter require a skilled and knowledgeable workforce. Regular cleaning and sterilization protocols must be strictly followed to prevent cross-contamination between batches. The calibration and maintenance of sensors and control equipment are essential to ensure accurate and reliable performance. Moreover, operators need to be trained to respond effectively to any deviations or anomalies in the fermentation process.

Looking ahead, ongoing research and technological advancements are expected to further enhance the capabilities of the 60L Stainless Tank Fermenter and similar systems. Developments in sensor technology will provide more accurate and detailed information about the internal conditions of the tank. Advances in process control algorithms and artificial intelligence will enable more predictive and adaptive control strategies, improving process efficiency and product quality.

In conclusion, the 60L Stainless Tank Fermenter for cell culture and microorganism fermentation represents a critical tool in the toolkit of modern biotechnology and industrial processes. Its ability to provide a controlled, scalable, and monitored environment for complex biological reactions makes it indispensable for the production of a wide range of valuable products and the advancement of scientific knowledge. As we continue to push the boundaries of what is possible in these fields, the importance and sophistication of such fermentation equipment are only set to increase.