Revolutionizing Industrial and Plant Cell Cultivation Processes

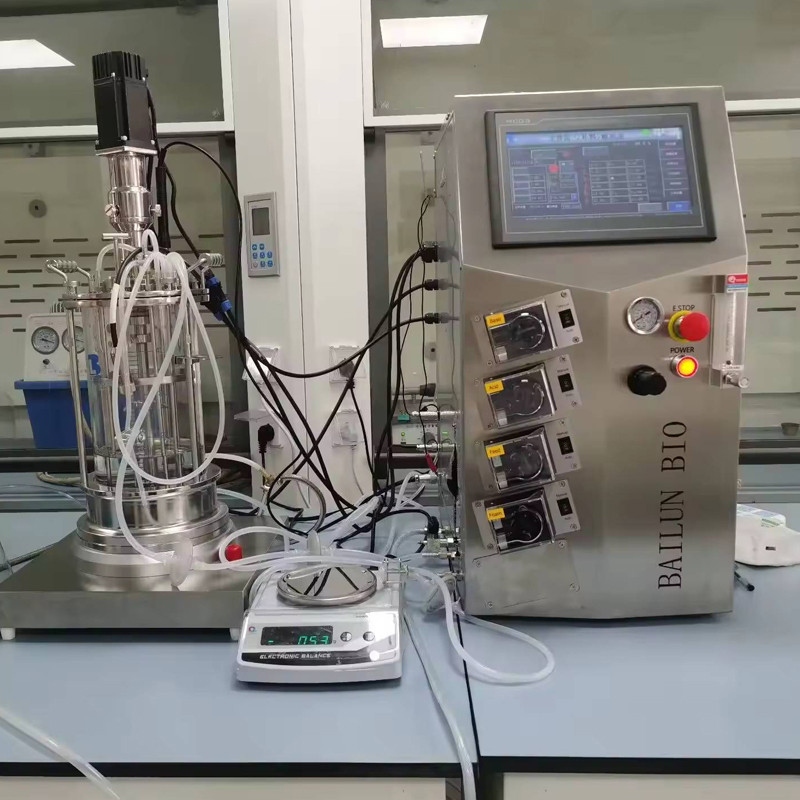

In the ever-evolving landscape of biotechnology and industrial manufacturing, the Stainless Steel Fermenter Bioreactor has emerged as a cornerstone of innovation and progress. This sophisticated equipment plays a vital role in diverse applications, from industrial-scale fermentation to the cultivation of plant cells for various purposes.

The Stainless Steel Fermenter Bioreactor offers several distinct advantages that make it indispensable in the industrial setting. The choice of stainless steel as the construction material is not arbitrary; it provides excellent durability, resistance to corrosion, and ease of sterilization. These properties ensure the bioreactor's longevity and hygiene, which are crucial for maintaining the integrity of the fermentation process.

In industrial fermentation, the bioreactor is designed to handle large volumes of substrates and microorganisms. It provides a controlled environment where parameters such as temperature, pH, dissolved oxygen, and agitation can be precisely regulated. This level of control is essential for optimizing the growth and metabolic activities of the microorganisms, thereby maximizing the yield and quality of the desired products.

For instance, in the production of biofuels, the Stainless Steel Fermenter Bioreactor allows for the efficient conversion of biomass into ethanol or other bioenergy sources. The controlled conditions inside the reactor promote the enzymatic breakdown of complex molecules and the subsequent fermentation processes, leading to a higher output of energy-rich compounds.

In the realm of pharmaceuticals, the bioreactor is utilized for the production of antibiotics, vaccines, and therapeutic proteins. The precise control over the environment within the stainless steel vessel ensures the consistent quality and purity of these critical medical products. This is of paramount importance in meeting the strict regulatory standards of the healthcare industry.

Turning our attention to the Plant Cell Cultivation Bioreactor, a specialized application of the stainless steel technology, it opens up new possibilities in the field of plant biotechnology. Plant cells have unique requirements compared to microorganisms, and the bioreactor is tailored to meet these needs.

One of the significant benefits of using a bioreactor for plant cell cultivation is the ability to provide a controlled microenvironment that mimics the conditions within a plant. This includes regulating factors such as light intensity and quality, nutrient composition, and hormone levels. By manipulating these parameters, researchers can induce plant cells to undergo specific metabolic pathways or differentiate into desired cell types.

For example, in the production of secondary metabolites such as plant-based drugs and flavors, the bioreactor enables the large-scale cultivation of plant cells that produce these valuable compounds. The controlled environment ensures consistent production and quality, reducing the reliance on traditional methods of extracting these compounds from wild plants, which may be environmentally unsustainable and limited in supply.

The use of stainless steel in the Plant Cell Cultivation Bioreactor also offers advantages in terms of sterility and cleanability. Plant cells are often more sensitive to contamination than microorganisms, and the smooth surface of stainless steel and its resistance to biofilm formation helps maintain a contamination-free environment.

Furthermore, the scalability of the Stainless Steel Fermenter Bioreactor is a key factor in its wide adoption. Whether for small-scale research and development or large-scale industrial production, the bioreactor can be designed and operated to meet the specific volume requirements. This flexibility allows for seamless transition from laboratory-scale experiments to full-scale manufacturing, reducing the time and costs associated with process optimization and scale-up.

However, operating and maintaining these bioreactors come with their own set of challenges. The complexity of the control systems requires skilled operators who understand the intricacies of the fermentation or cultivation processes. Regular monitoring and calibration of sensors, as well as maintenance of mechanical components such as agitators and pumps, are essential to ensure the smooth and reliable operation of the bioreactor.

In addition, the design and optimization of the bioreactor for specific applications require a deep understanding of the biological processes and the interaction between the cells and the environment. Computational modeling and process simulation tools are increasingly being used to predict and optimize the performance of the bioreactor before actual experimentation.

Looking ahead, the future of the Stainless Steel Fermenter Bioreactor appears promising. Advances in materials science, sensor technology, and process control are expected to further enhance the performance and functionality of these bioreactors. Integration with artificial intelligence and machine learning algorithms could enable real-time optimization and predictive maintenance, reducing downtime and improving overall productivity.

In conclusion, the Stainless Steel Fermenter Bioreactor, whether in its industrial fermentation or plant cell cultivation applications, represents a remarkable technological achievement. It provides a controlled and scalable platform for various biological processes, driving innovation and contributing to the development of sustainable and efficient solutions in multiple industries. As we continue to unlock the potential of this technology, it is likely to play an even more significant role in shaping the future of biotechnology and industrial manufacturing.