Cell Culture Bioreactors: From Mini Lab Setups to Advanced Cellular Growth Systems

In the ever-expanding field of biotechnology and biomedical research, cell culture bioreactors have emerged as indispensable tools for the efficient growth, manipulation, and study of cells. This article explores the diverse range of cell culture bioreactors, from mini lab bioreactors to large-scale systems, and their significant role in advancing scientific knowledge and practical applications.

Cell culture bioreactors provide a controlled environment that mimics the natural physiological conditions necessary for cells to thrive and perform their specific functions. These bioreactors are designed to regulate and maintain crucial parameters such as temperature, pH, dissolved oxygen, nutrient supply, and waste removal, ensuring optimal cell growth and productivity.

The mini lab bioreactor is a compact and versatile tool commonly used in research laboratories. These small-scale systems offer several advantages for early-stage experiments and feasibility studies. Due to their reduced size and footprint, mini lab bioreactors are cost-effective and require less space and resources. They allow researchers to conduct rapid experiments with small sample volumes, enabling the screening of different cell lines, culture conditions, and growth factors in a short period.

One of the key features of mini lab bioreactors is their ability to precisely control environmental parameters. For example, temperature control systems maintain a stable and optimal temperature range that is critical for enzymatic reactions and cellular metabolism. The pH regulation mechanism ensures that the culture medium remains within the appropriate pH range, which is essential for maintaining cellular homeostasis and protein functionality.

The controlled supply of dissolved oxygen is another crucial aspect in cell culture bioreactors. Aeration systems provide a continuous flow of oxygen to meet the metabolic demands of the cells, especially for aerobic cell types. At the same time, efficient agitation or mixing mechanisms ensure the uniform distribution of nutrients and oxygen throughout the culture, preventing the formation of concentration gradients and ensuring homogeneous cell growth.

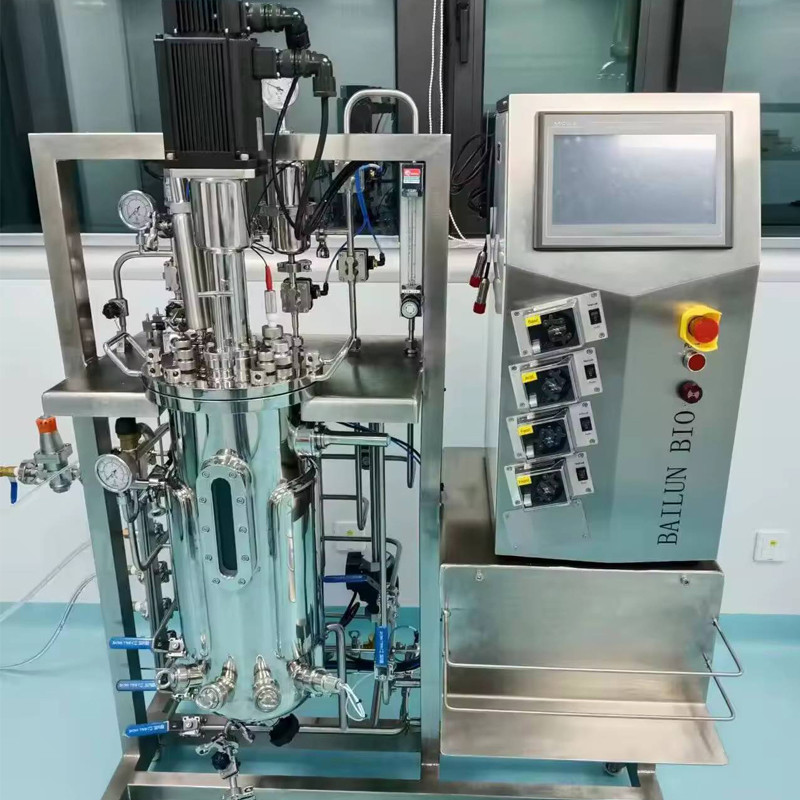

In addition to these basic parameters, mini lab Stainless Steel bioreactors often incorporate advanced monitoring and sensing technologies. These may include sensors for measuring cell density, metabolite concentrations, and oxygen consumption rates in real-time. This continuous monitoring provides valuable data for understanding the kinetics and dynamics of cell growth and metabolism, allowing for timely adjustments and optimizations of the culture conditions.

As research progresses and applications expand, larger-scale cell culture Fermenter bioreactors come into play. These systems are designed to handle larger volumes of cell cultures and are often used in industrial production settings or for large-scale clinical applications. For instance, in the production of therapeutic proteins, monoclonal antibodies, or vaccines, large-scale bioreactors are essential for meeting the high demand for these biomolecules.

The design and functionality of large-scale cell culture bioreactors build upon the principles established in mini lab setups but incorporate additional features to handle the increased complexity and scale of operation. Advanced fluid dynamics modeling and engineering are employed to ensure efficient mass transfer and heat dissipation, which are critical for maintaining a homogeneous environment within the large reactor volume.

Bioreactors for cell culture also play a crucial role in the field of tissue engineering and regenerative medicine.

By providing a controlled 3D environment, these bioreactors can support the growth and differentiation of cells into complex tissues and organoids. This offers great potential for the development of replacement tissues and organs, as well as for disease modeling and drug testing.

Furthermore, the use of cells bioreactors is not limited to mammalian cells. Microbial cells, such as bacteria and yeast, are also cultivated in specialized bioreactors for the production of antibiotics, enzymes, biofuels, and other valuable products. The design and operation of these bioreactors are tailored to the specific requirements and metabolic characteristics of the microbial species being cultured.

In recent years, significant advancements have been made in the field of cell culture bioreactors, driven by the need for more efficient, scalable, and sustainable cell-based processes. The integration of technologies such as microfluidics, single-cell analysis, and artificial intelligence is enabling more precise control and optimization of cell culture conditions.

For example, microfluidic bioreactors offer precise control over fluid flow and microenvironments at the single-cell level, providing new insights into cell-cell interactions and heterogeneity within a population. Single-cell analysis techniques allow for the characterization and selection of individual cells based on their specific properties and functions, which can improve the quality and productivity of cell cultures.

In conclusion, cell culture bioreactors have revolutionized the field of cell biology and biotechnology. Whether in a mini lab setting or a large-scale industrial facility, these bioreactors provide the means to study, manipulate, and produce cells and their products with unprecedented precision and efficiency.

As research continues and technological innovations unfold, cell culture bioreactors will undoubtedly play an even more crucial role in advancing healthcare, biotechnology, and other related fields, opening up new possibilities for disease treatment, drug discovery, and sustainable bio-production.