Industrial Equipment in Wine Production: The 5000-Liter Bioreactor and Beyond

In the world of wine production, the utilization of advanced industrial equipment is essential for achieving high-quality and consistent results. This article focuses on the significance of various industrial equipments, with a particular emphasis on the 5000-liter bioreactor and its role in the complex and artful process of winemaking.

The wine industry has come a long way from traditional, manual methods to highly mechanized and controlled operations. Industrial equipment plays a crucial role in every stage of wine production, from grape harvesting to the final bottling. These tools not only increase efficiency but also enable producers to maintain precise control over the quality and characteristics of the wine.

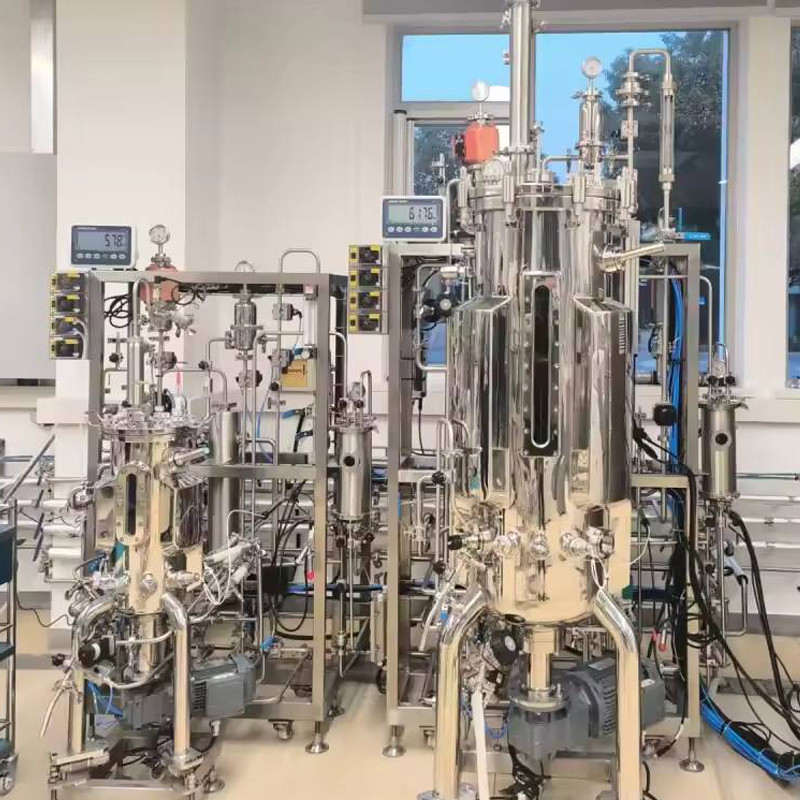

One of the key pieces of equipment in modern wine production is the 5000-liter bioreactor. This substantial vessel is designed to facilitate the fermentation process, which is a critical stage that transforms grape juice into wine. The 5000-liter capacity offers several advantages. It allows for larger batch sizes, which can be beneficial for commercial wineries looking to meet high market demands while maintaining consistency in product quality.

The design of the 5000-liter bioreactor is engineered to provide an optimal environment for the yeast and other microorganisms involved in fermentation. Temperature control is of paramount importance. The bioreactor is equipped with sophisticated systems to maintain a constant and appropriate temperature, as even slight variations can affect the kinetics of the fermentation process and the final flavor profile of the wine.

Proper aeration is another crucial aspect. The bioreactor is designed to supply the right amount of oxygen to the yeast, ensuring their healthy growth and efficient metabolism. This helps in the conversion of sugars into alcohol and the development of complex flavor compounds.

The material used in the construction of the bioreactor is also significant. High-quality stainless steel is often preferred due to its durability, resistance to corrosion, and ease of cleaning and sterilization. This ensures that the bioreactor remains hygienic and does not introduce any unwanted flavors or contaminants into the wine.

In addition to the 5000-liter Fermenter bioreactor, other industrial equipment is integral to the wine production process. Grape crushers and destemmers are used to process the harvested grapes, extracting the juice while removing stems and other debris. Presses are employed to further extract the juice from the crushed grapes, maximizing the yield.

During the clarification and filtration stages, specialized equipment helps remove sediment, proteins, and other impurities from the wine. This enhances the clarity and stability of the final product.

Storage tanks of various sizes and types are also essential. They are used to hold the wine at different stages of aging and maturation, allowing it to develop its unique flavors and aromas over time.

The control and monitoring systems associated with these industrial equipments are becoming increasingly advanced. Sensors and software enable winemakers to closely monitor and adjust parameters such as temperature, pH, and dissolved oxygen levels in real-time. This data-driven approach allows for more precise decision-making and optimization of the winemaking process.

Furthermore, the maintenance and proper operation of these equipments are critical. Regular cleaning, calibration, and servicing ensure that they perform consistently and reliably. Trained technicians and winemakers need to have a deep understanding of the equipment's functionality to troubleshoot any issues that may arise and to ensure that the wine production process proceeds smoothly.

The choice of industrial equipment depends on several factors, including the scale of production, the type of wine being produced, and the winery's budget and operational requirements. Smaller boutique wineries may opt for more compact and flexible equipment, while larger commercial operations might invest in large-scale, automated systems to handle higher volumes of production.

In conclusion, industrial equipment, especially the 5000-liter Cell Culture bioreactor, has transformed the landscape of wine production. It has enabled winemakers to combine traditional craftsmanship with modern technology, resulting in wines of exceptional quality and consistency. As the wine industry continues to evolve, ongoing innovation and improvement in industrial equipment will undoubtedly play a crucial role in shaping the future of this beloved beverage.