The 200L Stainless Steel Bioreactor and Its Role in Fermentation Processes

In the realm of modern biotechnology and industrial applications, the 200L Stainless Steel Bioreactor stands as a significant advancement, playing a crucial role in various fermentation processes. This article aims to explore the features, applications, and significance of this sophisticated piece of equipment.

The 200L Stainless Steel Bioreactor is engineered with precision and durability in mind. The choice of stainless steel as the material of construction is not incidental; it offers several key advantages. Stainless steel is highly resistant to corrosion, ensuring the longevity and integrity of the bioreactor even in the presence of harsh chemicals and sterilization processes. Its smooth surface also reduces the risk of microbial adhesion and biofilm formation, maintaining a hygienic environment for the fermentation process.

The 200L capacity of the bioreactor strikes a balance between scalability and operational manageability. It is large enough to handle significant production volumes, making it suitable for mid-scale industrial operations and research facilities. At the same time, it is not overly cumbersome to operate and monitor, allowing for efficient control and optimization of the fermentation parameters.

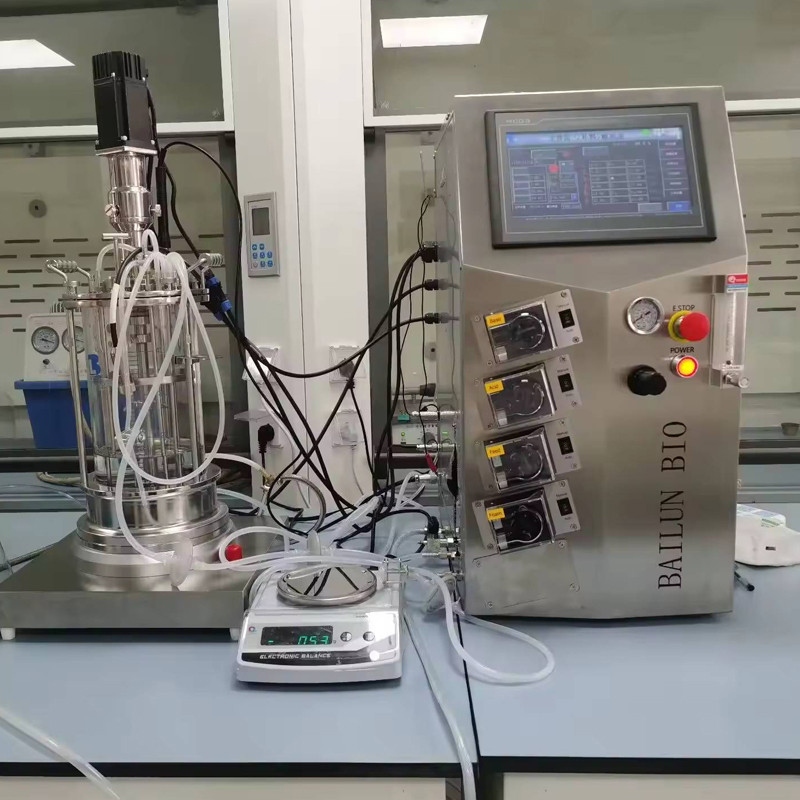

One of the primary functions of the 200L Stainless Steel Bioreactor is to provide a controlled environment for microbial growth and metabolic activities. The bioreactor is equipped with a sophisticated system for regulating parameters such as temperature, pH, dissolved oxygen, and agitation speed. Precise control of these factors is essential for optimizing the productivity and quality of the fermentation process.

For example, in the production of antibiotics, maintaining a specific temperature range and pH level is crucial for the efficient synthesis of the desired compounds by the microbial cultures. The ability to accurately monitor and adjust these parameters in real-time using the bioreactor's control systems ensures consistent and high-quality yields.

The bioreactor also plays a vital role in the field of biofuel production. Microbial fermentation of biomass to generate ethanol or other biofuels can be efficiently carried out in the 200L Stainless Steel Bioreactor. The controlled conditions within the vessel promote the enzymatic breakdown of complex organic matter and the subsequent conversion into usable fuel.

In the food and beverage industry, this bioreactor is employed in the production of various fermented products such as yogurt, cheese, and alcoholic beverages. The precise control over the fermentation process allows for the development of specific flavors, textures, and qualities that are characteristic of these products.

The design of the 200L Stainless Steel Bioreactor incorporates features that facilitate efficient mixing and aeration. Adequate mixing ensures uniform distribution of nutrients and oxygen throughout the culture, preventing the formation of gradients that could lead to uneven growth and product formation. Aeration systems supply the necessary oxygen for aerobic microbial metabolism, while also allowing for the removal of carbon dioxide and other metabolic by-products.

The bioreactor is often integrated with advanced monitoring and data acquisition systems. These systems provide real-time information on the various parameters and the status of the fermentation process. This data is not only valuable for immediate process control but also for post-process analysis and optimization.

Maintenance and sterilization of the 200L Stainless Steel Cell Culture Bioreactor are critical aspects of its operation. After each use, the bioreactor must undergo thorough cleaning and sterilization to eliminate any residual microorganisms or contaminants that could affect the next batch of fermentation. Regular inspection and servicing of the components, such as sensors, pumps, and valves, are necessary to ensure the reliable and efficient performance of the bioreactor over time.

In the context of research and development, the 200L Stainless Steel Bioreactor serves as an invaluable tool for experimentation and process optimization. Scientists can use it to test different microbial strains, substrates, and fermentation conditions to develop novel and improved production processes.

Looking forward, the 200L Stainless Steel Bioreactor is likely to undergo further technological advancements. Integration with artificial intelligence and machine learning algorithms could enable predictive control and optimization of the fermentation process. New materials and coatings may enhance the performance and longevity of the bioreactor, while improvements in energy efficiency and waste reduction will contribute to more sustainable operations.

In conclusion, the 200L Stainless Steel Bioreactor represents a significant technological asset in the fields of biotechnology, pharmaceuticals, food, and energy. Its ability to provide a controlled and scalable environment for fermentation processes makes it an indispensable component of modern industrial and research infrastructure. Continued innovation and improvement in its design and functionality will undoubtedly drive further progress and advancements in these sectors, contributing to the development of new products and solutions to meet the growing global demands.