Industrial Fermenter Bioreactors and Laboratory Fermentation Tanks: Driving Innovation in Bioprocessing

In the dynamic landscape of modern bioprocessing, the Industrial Fermenter Bioreactor and the Laboratory Fermentation Tank play crucial roles, shaping the way we produce a wide range of valuable products, from pharmaceuticals and biofuels to food and beverages.

The Industrial Fermenter Bioreactor is the workhorse of large-scale production. These massive vessels are engineered to handle the demands of continuous and efficient operation in an industrial setting. Their design incorporates advanced features to ensure optimal conditions for microbial growth and metabolite production.

One of the key aspects of an industrial fermenter bioreactor is its size and capacity. These systems are often several thousand liters or more, allowing for the production of significant quantities of the desired product. The construction materials, typically stainless steel, are chosen for their durability, resistance to corrosion, and ease of cleaning and sterilization.

The control systems in industrial fermenter bioreactors are highly sophisticated. They monitor and regulate parameters such as temperature, pH, dissolved oxygen, and agitation speed with great precision. This level of control is essential to maintain the consistency and quality of the final product. For example, in the production of antibiotics, maintaining a narrow range of pH and temperature is critical for the efficient synthesis of the active compound by the microbial culture.

In addition to these basic parameters, industrial fermenter bioreactors also incorporate systems for nutrient supply and waste removal. The precise management of these processes ensures that the microorganisms have a constant supply of essential nutrients while toxic by-products are efficiently eliminated. This balance is crucial for maximizing the productivity and lifespan of the culture.

The scalability of industrial fermenter bioreactors is another important feature. As the demand for a particular product increases, these systems can be expanded or replicated to meet the growing production needs. However, scaling up a bioprocess is not simply a matter of increasing the size of the vessel; it requires a detailed understanding of the underlying biological and engineering principles to ensure that the process remains efficient and reliable at a larger scale.

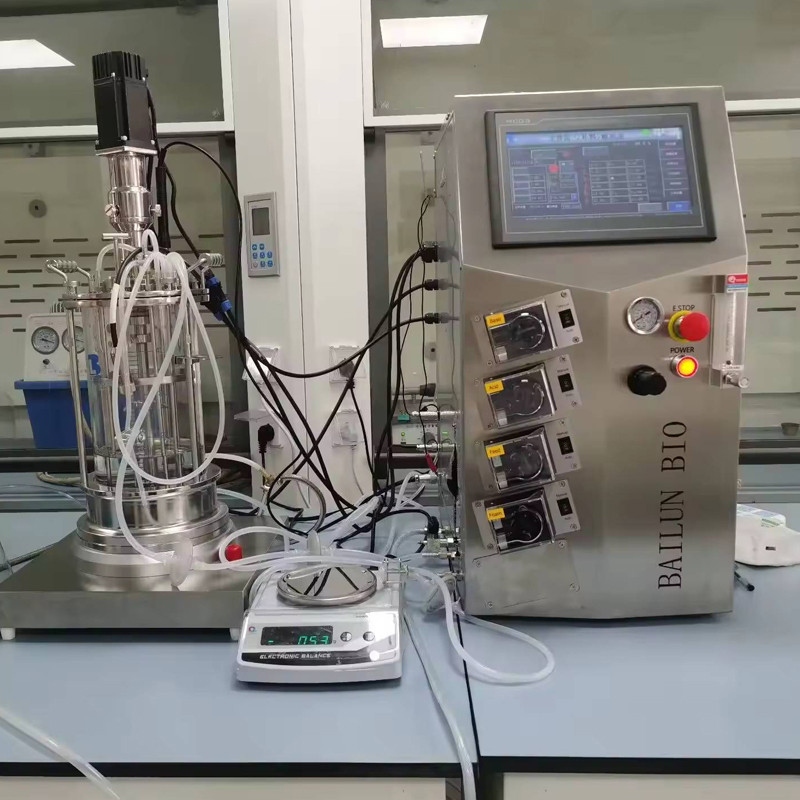

Turning our attention to the Laboratory Fermentation Tank, it serves as the proving ground for new bioprocesses and the optimization of existing ones. These smaller-scale systems are indispensable in the research and development phase of bioprocessing.

The laboratory fermentation tank allows researchers to test different microbial strains, growth media, and process conditions in a controlled environment. By manipulating these variables, they can identify the most promising combinations before moving to industrial-scale production. This iterative process of experimentation and optimization helps to minimize risks and maximize the chances of success in large-scale operations.

The flexibility of the laboratory fermentation tank is a significant advantage. It can be easily reconfigured to accommodate different experiments and can be used to study the kinetics and dynamics of the fermentation process in detail. Sophisticated monitoring and sampling capabilities enable researchers to collect real-time data on microbial growth, substrate consumption, and product formation, providing valuable insights into the underlying mechanisms of the process.

Despite their differences in size and application, both the industrial fermenter bioreactor and the laboratory fermentation tank share some common challenges and considerations. Maintaining sterility is of utmost importance in both cases to prevent contamination by unwanted microorganisms, which could compromise the quality and yield of the product. The design and operation of the equipment must also take into account factors such as energy consumption, process efficiency, and environmental impact.

In recent years, there have been significant advancements in the technology of both industrial fermenter bioreactors and laboratory fermentation tanks. The integration of sensors and automation has led to more precise control and monitoring of the fermentation process. The development of novel materials and coatings has improved the biocompatibility and performance of the vessels. Additionally, the application of computational modeling and simulation tools has enabled better prediction and optimization of the bioprocess, reducing the time and cost associated with experimentation.

Looking to the future, the continued evolution of these bioprocessing tools is expected to drive further innovation in the field. Advances in synthetic biology and metabolic engineering will create new opportunities for the production of complex molecules and the development of more efficient bioprocesses. The integration of artificial intelligence and machine learning algorithms will enable real-time optimization and predictive maintenance of the equipment, improving overall productivity and reliability.

In conclusion, the Industrial Fermenter Bioreactor and the Laboratory Fermentation Tank are integral to the advancement of bioprocessing. Their seamless collaboration, from the laboratory to the factory floor, is essential for meeting the increasing demands of various industries and for driving the development of novel and sustainable bioproducts. As technology progresses, these tools will continue to play a vital role in shaping the future of biotechnology and contributing to a more sustainable and prosperous world.